Intellix BMT 300

Bushing Monitoring and Partial Discharge Detection for Transformers

Bushings account for a large proportion of High Voltage (HV) substation failures, often causing severe and costly damages. Preventive maintenance, early replacement and regular off-line testing have been employed to address this issue in the past. Now, technology exists that enables asset owners to detect impending failures and reduce their maintenance costs.

Intellix BMT 300, a bushing monitoring system for transformers that can detect and diagnose problems before they occur, helping improve power reliability at utilities, industrial metals businesses, and petrochemical companies. It is available stand-alone or as a comprehensive solution integrated with GE’s Kelman TRANSFIX™ DGA analyzer and PERCEPTION software for an in-depth view of transformer health.

In addition to increasing reliability for power utilities, the Intellix BMT 300 also supports numerous applications for several industries around the globe. For industrial metals companies, the Intellix BMT 300 can monitor bushing conditions to avoid unplanned production stoppages or partial discharge on over-stressed assets in aluminum or steel plants. For petrochemical companies, the Intellix BMT 300 can detect developing arcing faults with transformers in flammable environments and monitor bushing health to avoid significant failures.

The BMT 300 provides customers with several key benefits, including:

- Continuous monitoring for early detection of possible problems.

- Partial Discharge (PD) activity correlation for faster identification of potential arcing faults.

- Condition-based maintenance resulting in reduced downtime, less site visitsand lowered maintenance costs.

- Seamless integration with GE's Kelman TRANSFIX DGA analyzer and PERCEPTION software for a comprehensive, in-depth view of the entire transformer health.

Applications

Power Utilities

- Enables condition-based maintenance of transformer bushings

- Designed for various three phase configurations

Metals

- Monitors bushing conditions to avoid unplanned production stoppage

- Monitors PD in over-stressed assets in aluminum or steel mills

Petrochemical

- Detects arcing faults with transformers

- Monitors bushing health to avoid catastrophic failures of transformers

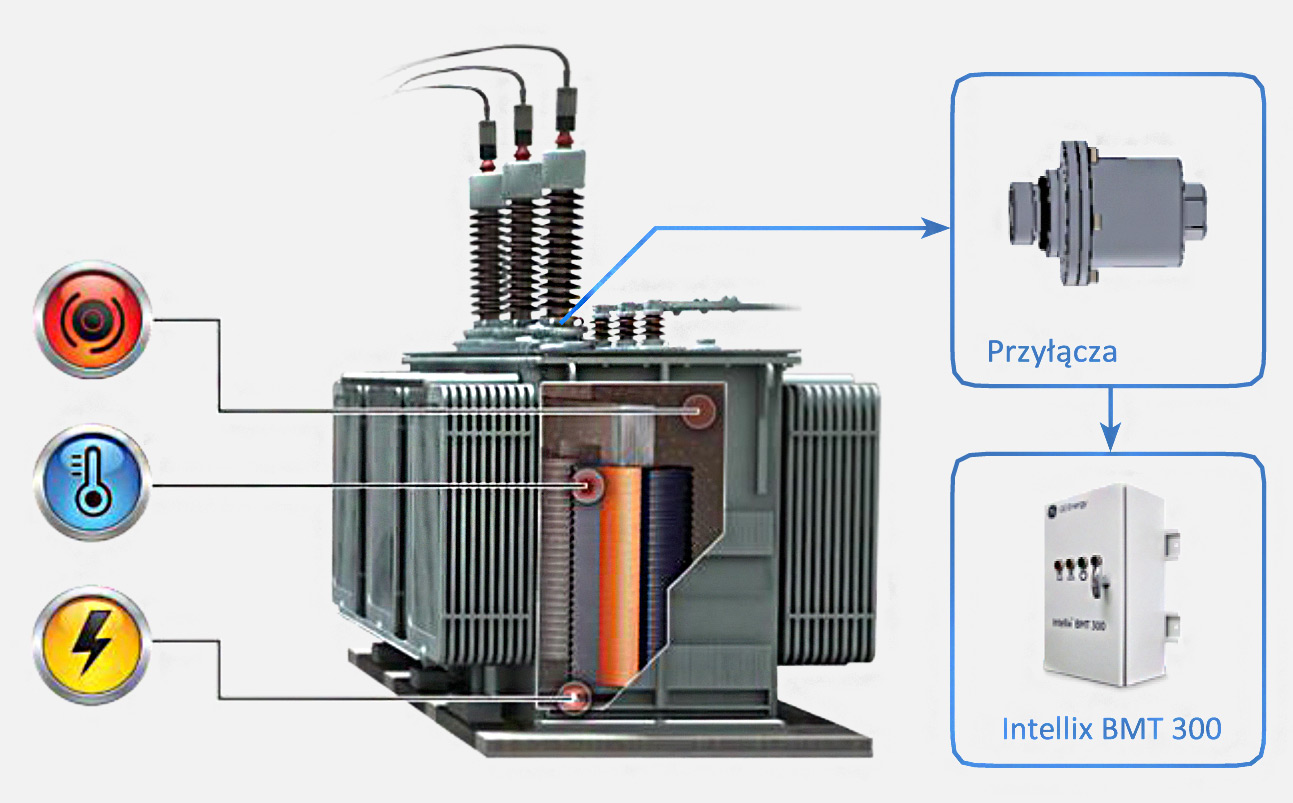

Example of GE’s Intellix BMT 330 Solution Installed on a Three-Phase Transformer

- Gas analyzer classifies the fault types, providing valuable insights into the transformers condition

- The value of the transformer can be estimated, allowing the use of expensive components

- Transformer aging can be calculated so that expensive failures can be avoided

- Transformer faults are detected in their infancy, enabling fast remedial response

- Monitors up to 6 bushings

- Advanced discrimination using additional sensors